Neodymium Iron Boron rare earth magnets are utilised in power generation turbines. A multitude of these magnets are bonded together to increase the overall level of magnetism. This process leads to two potential issues: Firstly, any adhesive or coating between the magnets acts as an air gap and thus reduces the level of magnetism and secondly NdFeB magnets corrode extremely aggressively. This corrosion issue is exacerbated by the environmental conditions that the wind turbines face.

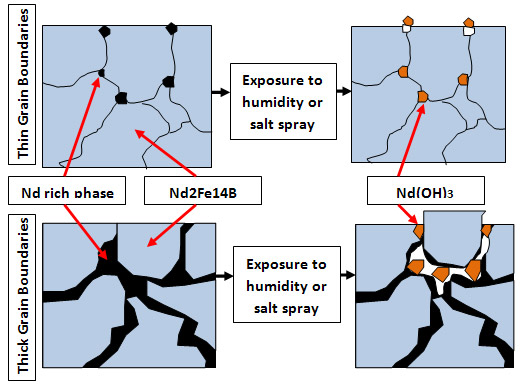

The corrosion mechanism for NdFeB magnets is detailed in Figure 1. This shows that when exposed to water or humid conditions, the Neodymium rich layers at the grain boundaries react to form Neodymium Hydroxide. The effect of this conversion from Nd to Nd(OH)3, is a large volume increase along the grain boundaries, leading to cracking and degradation of magnet properties.

Curtiss Wright Surface Technologies (CWST) has been working on a solution to these issues. This involved developing a high grade anti-corrosion coating with minimal coat thickness (effective air gap). The current market leader for corrosion protection is CWST’s own Everlube 6155 providing 500hours protection in the ASTM B117 salt spray test.

After extensive studies and trials, CWST is pleased to announce they have successfully developed a coating system which will provide 1000hours salt spray resistance for NdFeB magnets at a coating thickness of just 25um. This NEW coating system – Everlube 1155 is environmentally friendly, easy to apply and a cost effective solution to this critical problem.

Figure 1: Shows the corrosion mechanism for NdFeB rare earth magnets.

© 2024 Curtiss-Wright Corporation | User agreement | Privacy Notice | Cookies | Sitemap | T&Cs | GPG | Investor Relations | Terms of Use